-

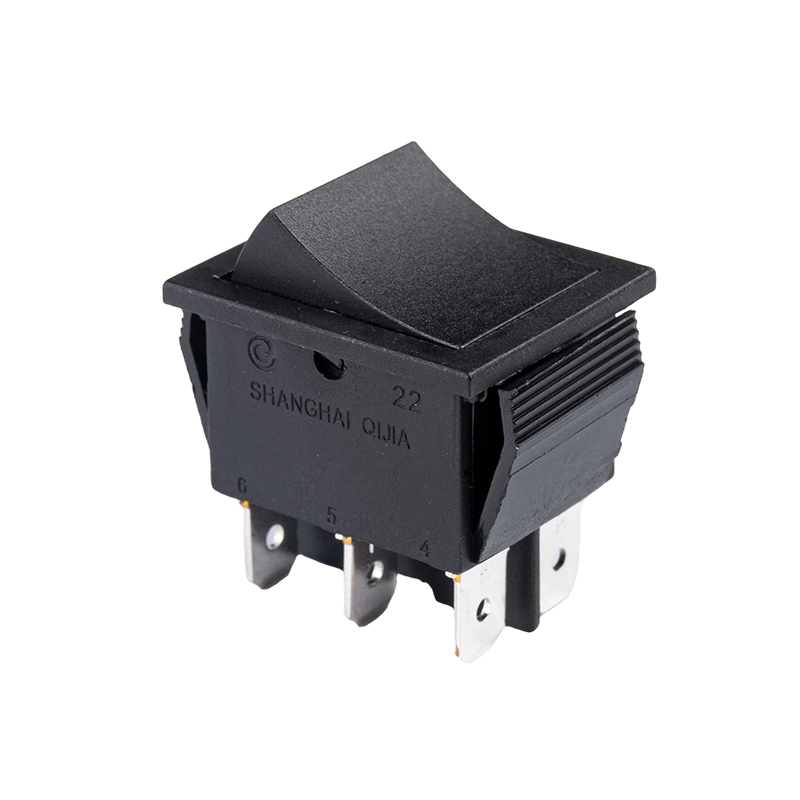

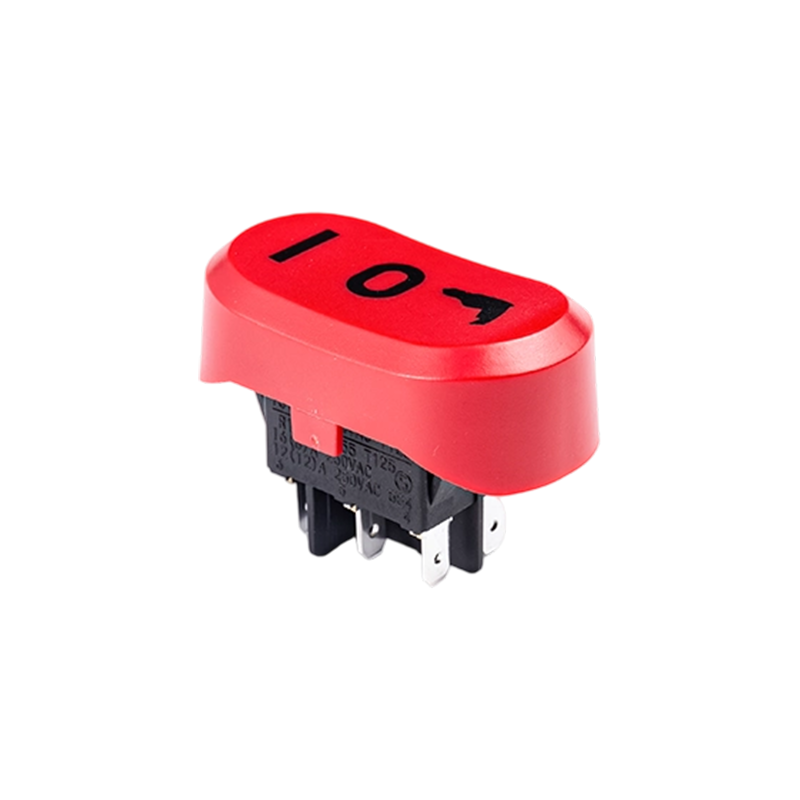

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

Rocker Switches: The Essential Guide for Modern Electronics and Industrial Applications

2026.01.21

2026.01.21

Industry News

Industry News

Understanding Rocker Switches and Their Applications

Rocker switches are widely used electrical components that allow users to control circuits with a simple rocking motion. They are favored for their reliability, durability, and ease of operation, making them essential in a range of applications from household appliances to industrial machinery. Unlike push-button or toggle switches, rocker switches provide a clear on/off indication through their rocking mechanism, which improves operational safety and user experience.

Key Types of Rocker Switches

Rocker switches come in various types depending on the required function and application environment. Understanding the differences helps in selecting the right switch for specific needs.

Single Pole Single Throw (SPST)

SPST rocker switches are the most basic type, controlling a single circuit with two positions: ON and OFF. They are widely used in simple devices like lamps, power strips, and small household appliances.

Single Pole Double Throw (SPDT)

SPDT rocker switches can control two separate circuits or provide alternative current paths. These are commonly used in automotive applications, audio equipment, and industrial machinery where switching between two circuits is necessary.

Illuminated Rocker Switches

These switches include an integrated LED indicator, which provides visual confirmation of the switch’s status. Illuminated rocker switches are particularly useful in low-light environments or when quick visual identification is needed.

Important Specifications to Consider

Choosing the right rocker switch requires attention to several technical specifications that impact performance and safety.

Current and Voltage Ratings

Rocker switches are rated for maximum current and voltage. Selecting a switch with insufficient ratings can lead to overheating, failure, or even electrical hazards. Always match the switch’s rating with the operational requirements of your device.

Mechanical Lifespan

The mechanical lifespan of a rocker switch, typically measured in tens or hundreds of thousands of cycles, indicates how long it can reliably function. Industrial and automotive applications often require switches with extended lifespans to withstand frequent use.

Environmental Protection Ratings

Many rocker switches are rated with IP codes indicating their resistance to dust and moisture. IP65 or higher switches are suitable for outdoor and harsh environments, ensuring durability and safety in demanding conditions.

Common Materials and Design Features

Rocker switches are designed with a combination of materials to ensure durability, safety, and user comfort.

- Housing: Usually made from high-strength thermoplastics or nylon to resist impact and heat.

- Contacts: Often made of silver or copper alloys to ensure optimal conductivity and reduce oxidation.

- Actuator: Designed ergonomically to provide tactile feedback and prevent accidental switching.

- LEDs and lenses (for illuminated types): Made with durable polycarbonate for long-lasting illumination.

Rocker Switch Applications Across Industries

Rocker switches are highly versatile, finding applications in a variety of sectors.

| Industry | Application |

| Automotive | Control of lights, fans, and auxiliary equipment |

| Home Appliances | Power control in coffee makers, washing machines, and heaters |

| Industrial Equipment | Machine control, safety shut-offs, and process switching |

| Marine and Outdoor | Waterproof switches for boats, outdoor lighting, and equipment |

Tips for Selecting the Right Rocker Switch

When choosing a rocker switch, consider both technical and practical factors to ensure optimal performance and safety.

- Match the current and voltage ratings with your device’s requirements.

- Determine if an illuminated switch is necessary for visibility.

- Consider environmental exposure and choose an IP-rated switch if needed.

- Ensure the mechanical lifespan aligns with expected usage frequency.

- Check for ergonomic design for ease of use in daily operation.

Conclusion

Rocker switches are simple yet essential components that enhance the usability, safety, and functionality of countless devices across industries. By understanding the types, specifications, and applications of rocker switches, engineers and consumers alike can make informed choices that optimize performance and ensure reliability over time.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى