-

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

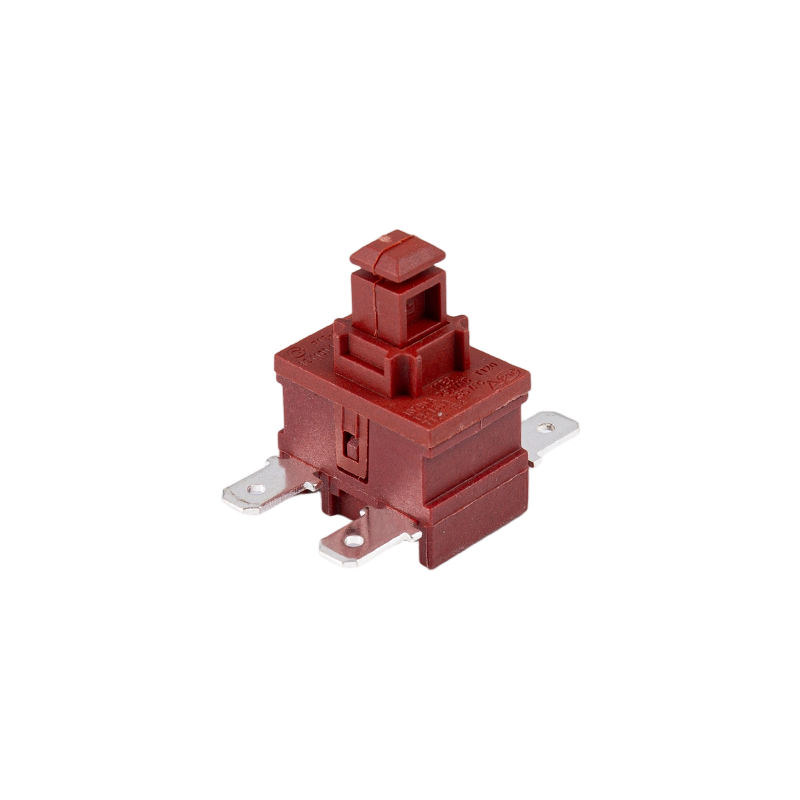

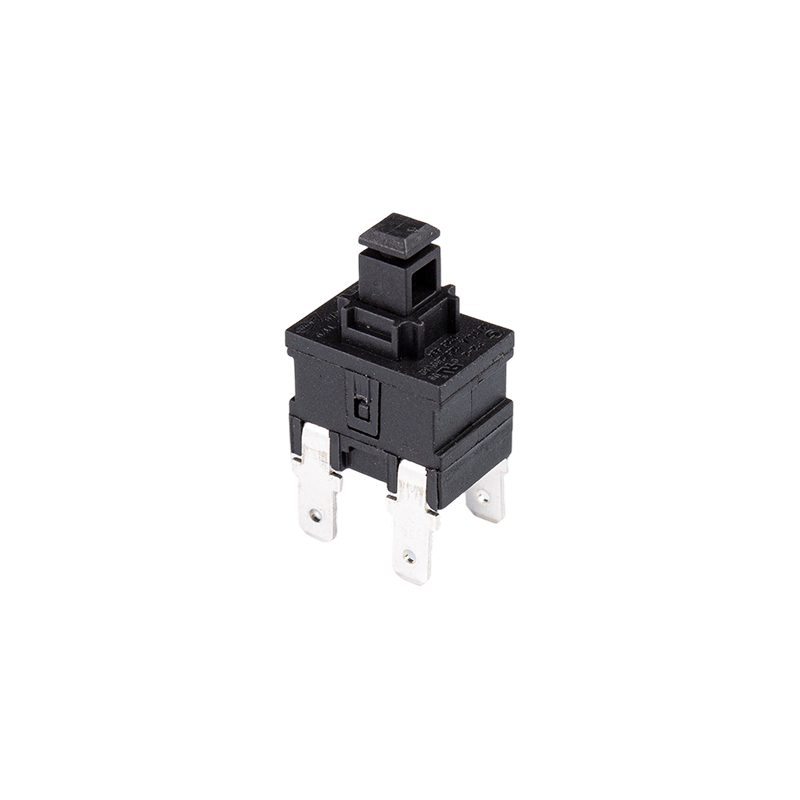

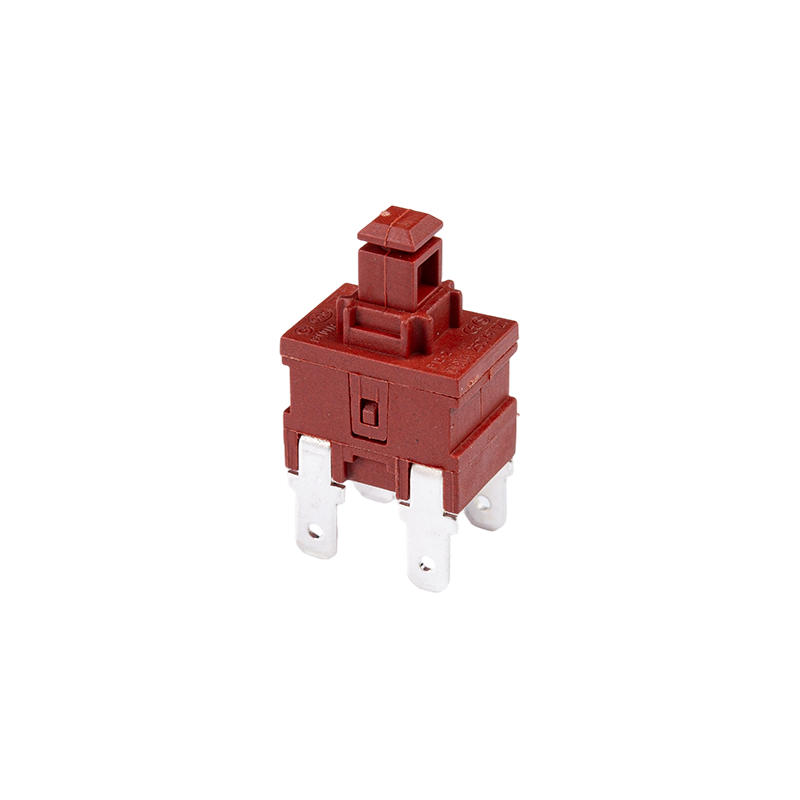

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

Push Button Switches Explained: Selection, Wiring, and Performance Factors Engineers Care About

2026.01.27

2026.01.27

Industry News

Industry News

What a Push Button Switch Is and How It Actually Works

A push button switch is a momentary or maintained electrical switch that controls a circuit by applying mechanical pressure. When the button is pressed, internal contacts either close or open the circuit, allowing or interrupting current flow. Unlike rotary or toggle switches, push button switches are designed for fast, intuitive operation, making them ideal for control panels, machinery interfaces, consumer electronics, and safety systems.

Internally, most push button switches rely on spring-loaded mechanisms. In momentary types, the contacts return to their original state once pressure is released. Maintained (latching) types remain in the actuated state until pressed again. Understanding this internal behavior is essential when selecting a switch for automation, signaling, or power control.

Common Types of Push Button Switches Used in Real Applications

Momentary vs. Latching Push Buttons

Momentary push button switches are widely used for reset functions, doorbells, PLC inputs, and test equipment because they only stay active while pressed. Latching push buttons are preferred for power control, start-stop stations, and lighting circuits where a maintained state is required without continuous pressure.

Normally Open and Normally Closed Contacts

Push button switches are classified by their default electrical state. Normally open (NO) contacts close when pressed, while normally closed (NC) contacts open when pressed. Many industrial push buttons combine both NO and NC contacts, enabling flexible control logic and enhanced safety.

- Momentary NO: Signal input or trigger command

- Momentary NC: Emergency stop or fault detection

- Latching NO/NC: Power and mode selection

Key Electrical and Mechanical Specifications That Matter

Selecting a push button switch requires more than matching size and appearance. Electrical ratings such as voltage, current capacity, and contact resistance directly affect safety and service life. Using an underrated switch can lead to overheating, arcing, or premature failure.

| Rated Voltage | Determines compatibility with AC or DC circuits |

| Rated Current | Maximum load the contacts can safely handle |

| Mechanical Life | Number of press cycles before mechanical wear |

| Electrical Life | Cycles under rated load conditions |

Mechanical characteristics such as actuation force, travel distance, and tactile feedback also influence user experience. For high-frequency operation, low-force switches reduce fatigue, while rugged industrial environments often require higher actuation force to prevent accidental triggering.

How to Choose the Right Push Button Switch for Your Project

The correct push button switch depends heavily on the operating environment and application purpose. For outdoor or industrial use, switches with high IP ratings protect against dust, water, and oil exposure. In medical or food-processing equipment, sealed and easy-to-clean designs are critical.

- Control panels: Metal-bodied, panel-mount push buttons

- Consumer electronics: Compact PCB-mounted push buttons

- Emergency systems: Mushroom-head, NC push buttons

Illuminated push button switches add visual feedback, helping operators quickly identify machine status or active functions. When choosing illuminated models, matching the LED voltage and color with system requirements is essential to avoid wiring issues or inconsistent brightness.

Installation, Wiring, and Maintenance Best Practices

Proper installation ensures reliable operation and long service life. Panel-mount push button switches should be securely fastened to prevent loosening from vibration. Wiring terminals must be tightened to the manufacturer’s torque specification to avoid intermittent connections.

Routine inspection helps detect early signs of wear, such as increased actuation force or delayed contact response. In high-duty-cycle systems, replacing push button switches proactively can prevent unexpected downtime and improve overall system reliability.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى