-

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

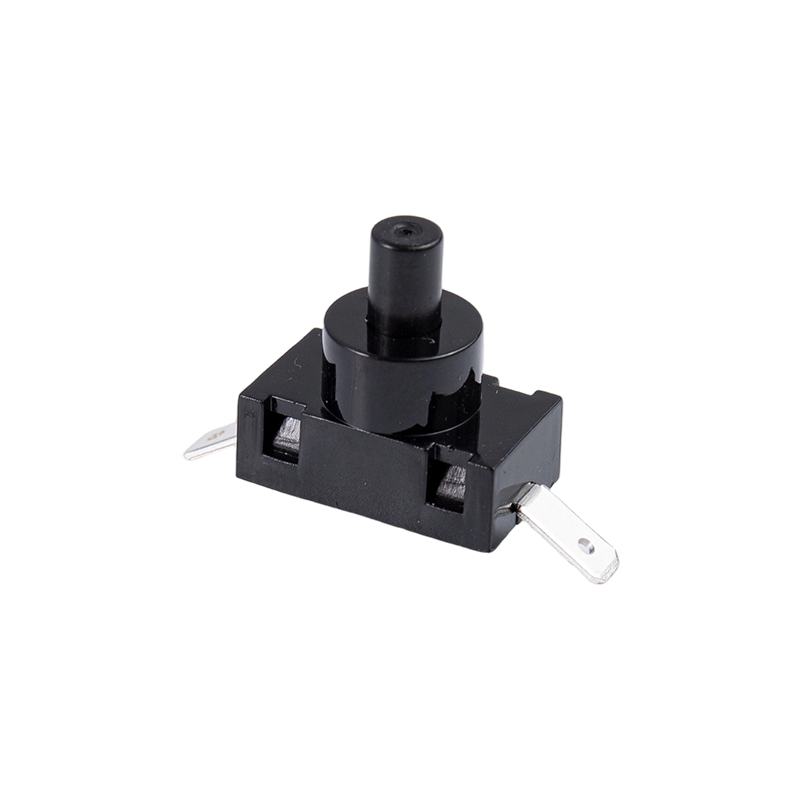

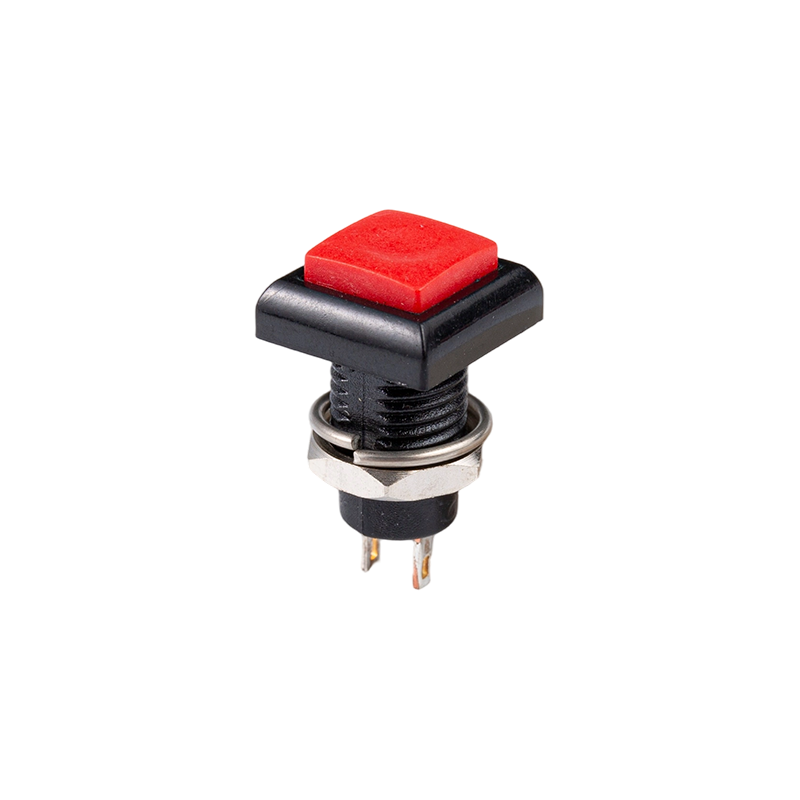

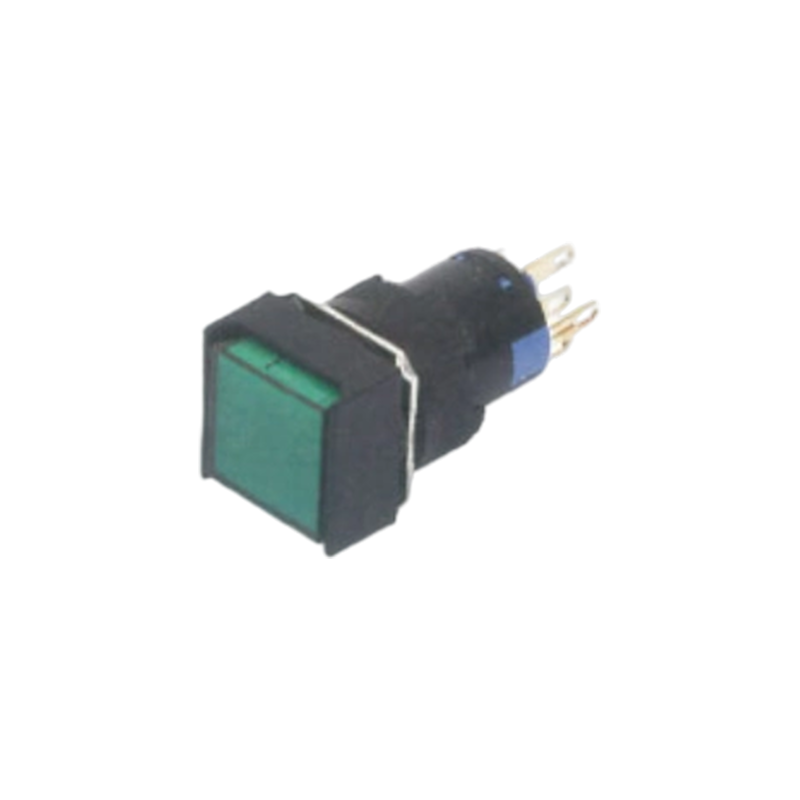

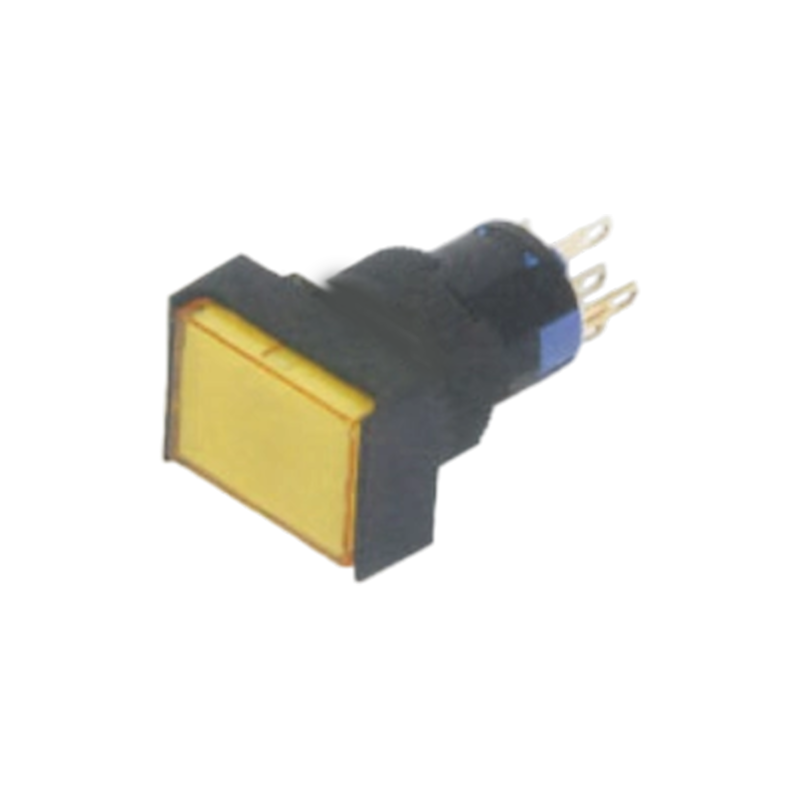

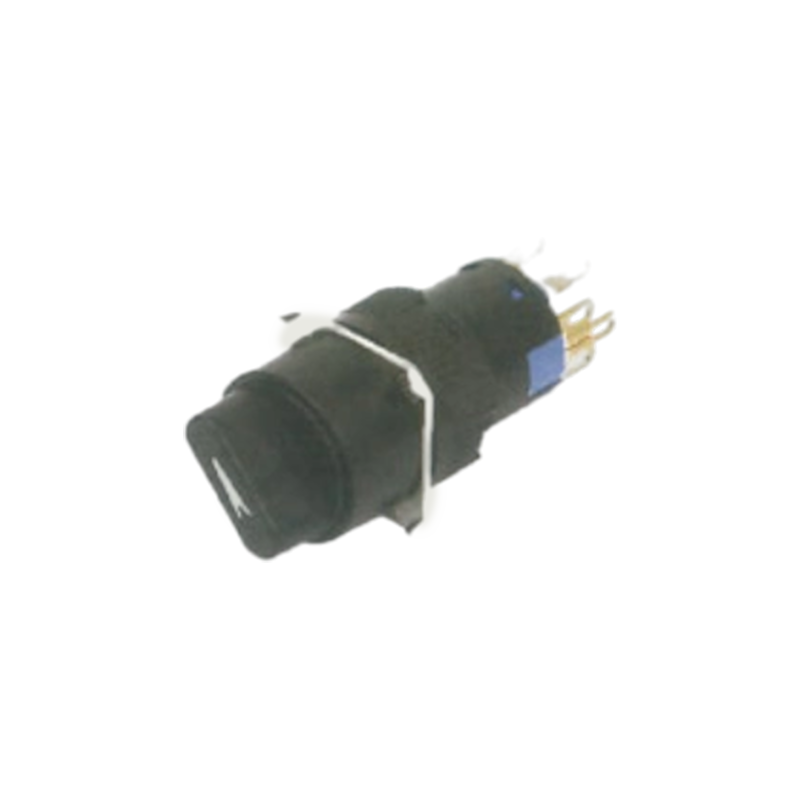

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

The Engineer’s Guide to Precision: Choosing the Right Button Switch for High-Performance Electronics

2026.01.04

2026.01.04

Industry News

Industry News

Understanding the Mechanics of Button Switches

Button switches, often referred to as push-button switches, are fundamental components in electrical engineering that allow or interrupt the flow of current. Unlike toggle or rocker switches, these are actuated by a simple pressing motion. The internal mechanism typically involves a spring-loaded plunger that, when depressed, either connects or disconnects the internal conductive contacts. Understanding the physical feedback and the electrical rating is crucial when selecting a switch, as the tactile response (the "click") and the travel distance can significantly impact the user experience in consumer electronics and industrial controls alike.

Momentary vs. Maintained Action

One of the primary distinctions in button switch technology is the action type. A momentary switch only remains in its active state as long as it is being pressed; once the pressure is released, the spring returns it to its original position (e.g., a keyboard key or a doorbell). Conversely, a maintained (or latching) switch stays in the new position after being pressed and requires a second press to revert to its original state, much like a power button on a desktop computer.

Key Specifications for Industrial and Commercial Applications

When integrating button switches into a project, technical specifications determine the component's longevity and safety. Voltage and current ratings are the most critical factors; exceeding these can lead to arcing, which damages contacts and can cause fire hazards. Furthermore, the environment in which the switch operates dictates the need for specific Ingress Protection (IP) ratings, which measure the switch’s resistance to dust and moisture.

| Specification | Description | Common Values |

| Contact Resistance | The resistance to current flow across closed contacts | < 50mΩ |

| Dielectric Strength | Maximum voltage the switch can withstand without breakdown | 1,000V AC/min |

| Mechanical Life | The number of press cycles before failure | 100,000 to 1,000,000 cycles |

| Operating Temp | Safe temperature range for operation | -25°C to +85°C |

Common Contact Configurations

The way a button switch is wired into a circuit is defined by its poles and throws. This configuration determines how many separate circuits the switch can control and how many positions the switch can activate. Choosing the correct configuration is essential for complex logic or safety-critical interruptions.

- SPST (Single Pole, Single Throw): The simplest type, featuring two terminals to open or close a single circuit.

- SPDT (Single Pole, Double Throw): One input terminal that can be connected to one of two output terminals, allowing the user to switch between two different circuits.

- DPST (Double Pole, Single Throw): Controls two separate circuits simultaneously with a single press, often used for safety to disconnect both hot and neutral lines.

- DPDT (Double Pole, Double Throw): Equivalent to two SPDT switches controlled by one button, used for reversing polarity in DC motors or complex signal routing.

Material Selection and Contact Plating

The materials used for both the housing and the internal contacts dictate the switch's performance in specific environments. While plastic housings are cost-effective for indoor consumer goods, stainless steel or brass housings are preferred for vandal-resistant applications or harsh outdoor environments. Internally, the contact plating is what ensures a reliable electrical connection over time.

Silver vs. Gold Plating

Silver is the most common contact material because it has excellent conductivity and can handle higher currents. However, silver can tarnish over time, which might affect low-voltage signals. Gold plating is used for "dry circuits" or low-current applications (typically under 100mA). Since gold does not oxidize or corrode, it provides superior reliability for logic-level signals in computing and telecommunications where signal integrity is paramount.

Mounting Styles and Practical Installation

The physical integration of a button switch depends on the design of the device's housing or PCB. Selecting the wrong mounting style can lead to mechanical failure or assembly difficulties. Engineers must decide early in the design phase whether the switch will be a primary user interface element or an internal configuration button.

- Panel Mount: These switches are designed to be installed through a hole in an enclosure and secured with a nut, making them ideal for control panels and machinery.

- PCB Mount (Through-Hole): The terminals are inserted through holes in a printed circuit board and soldered on the underside, providing strong mechanical support.

- Surface Mount (SMD): These are soldered directly onto the surface of a PCB, allowing for smaller, more compact device designs but offering less mechanical strength than through-hole options.

- Snap-In Mount: Features plastic clips that hold the switch in place within a panel cutout without the need for additional hardware, speeding up the assembly process.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى