-

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

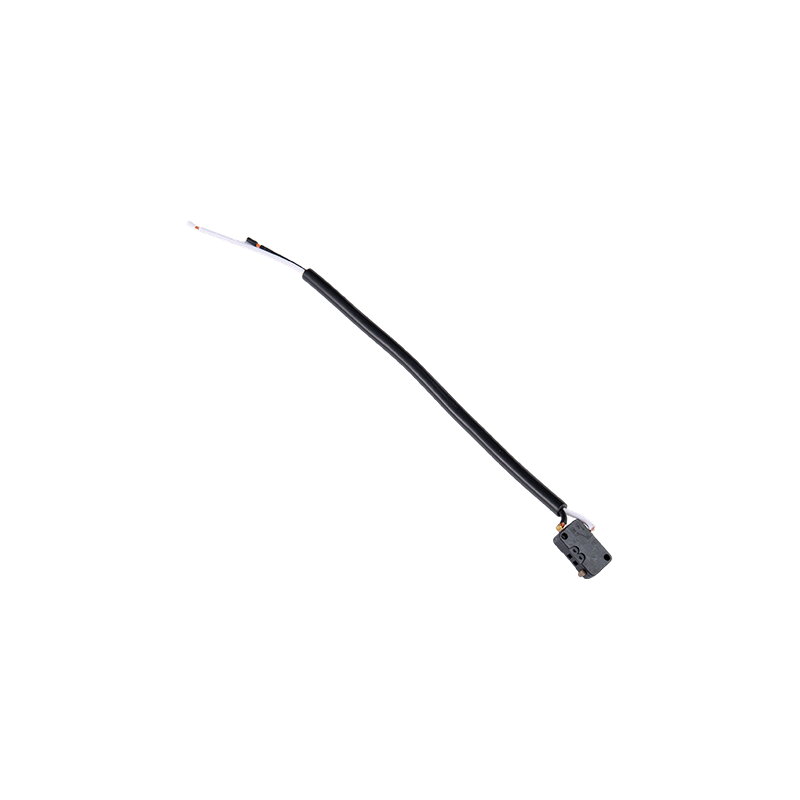

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

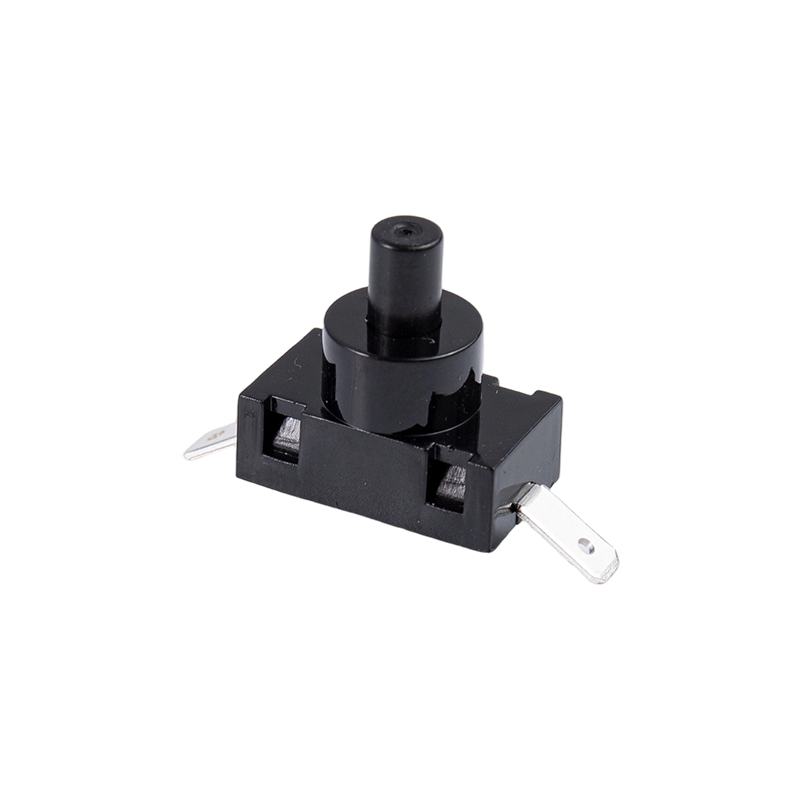

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

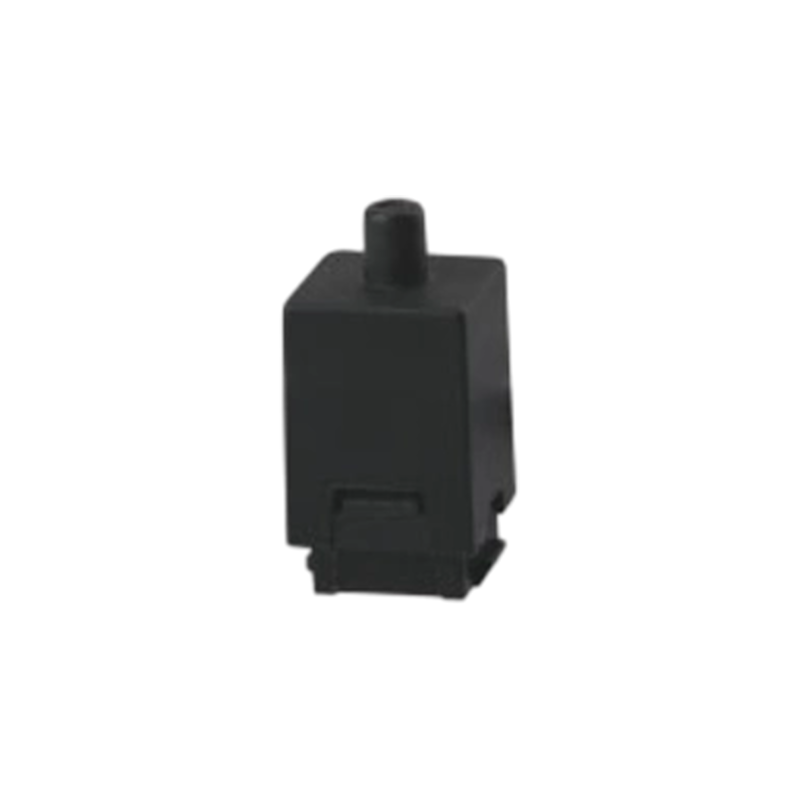

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

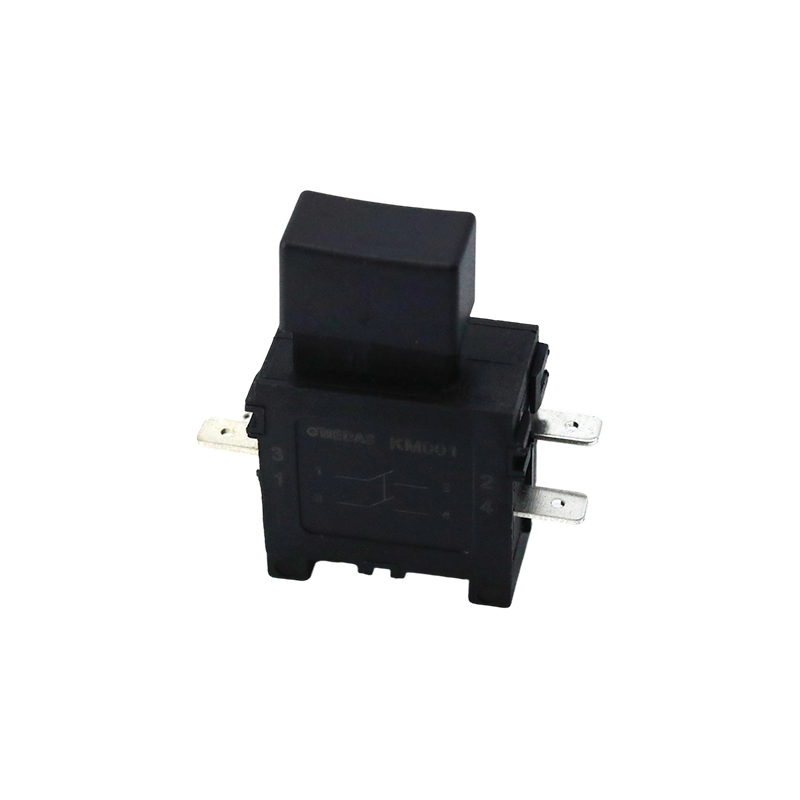

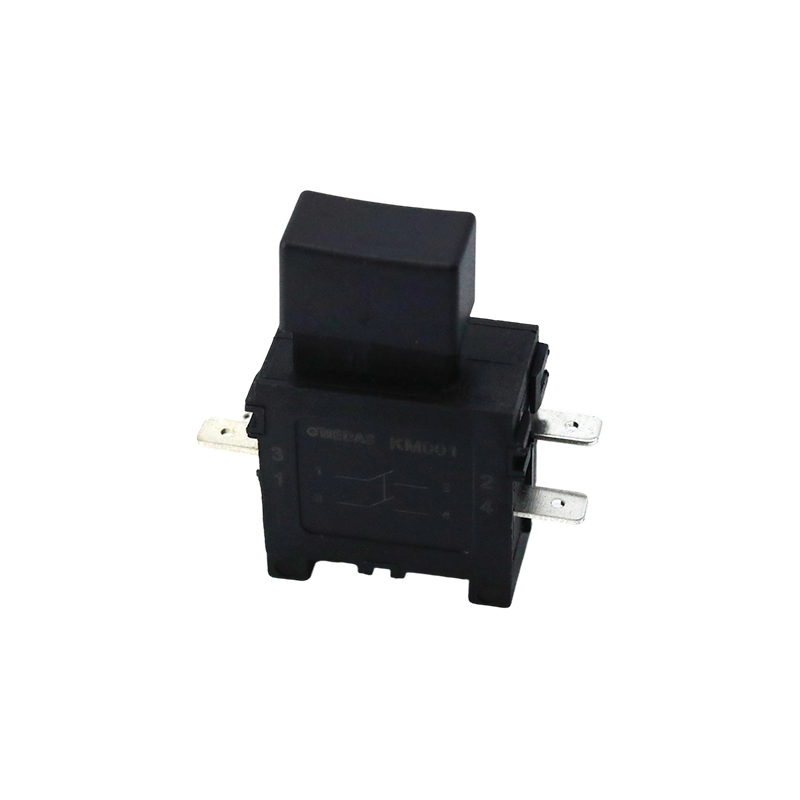

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

Are You Using the Right Trigger Switches for Your High-Performance Projects?

2026.01.07

2026.01.07

Industry News

Industry News

Understanding the Mechanics of Trigger Switches

Trigger switches are specialized momentary contact switches designed to be operated by a finger pull, most commonly found in power tools, gaming controllers, and industrial pendants. Unlike standard toggle or rocker switches, a trigger switch is engineered for ergonomic interaction and varying degrees of control. The internal mechanism typically consists of a spring-loaded plunger that, when depressed, bridges electrical contacts to complete a circuit. In many modern applications, these switches do not just function as simple "on/off" gates; they often incorporate complex internal components like potentiometers or Hall effect sensors to provide nuanced feedback to the device's control board.

Core Varieties of Trigger Switch Technology

Single-Speed vs. Variable Speed Triggers

The most basic distinction in trigger technology is the method of power delivery. A single-speed trigger operates on a binary logic: the circuit is either open or closed. These are frequently used in simple appliances where constant RPM is required. Conversely, variable speed triggers allow the user to dictate the output based on the depth of the pull. This is achieved by increasing or decreasing the resistance within the circuit, which in turn regulates the voltage or signal sent to the motor or processor.

Safety Interlocks and Lock-on Buttons

Safety is a paramount concern in trigger design, particularly for high-torque power tools. Many trigger switches are paired with a "safety lock-off" button that must be engaged before the trigger can be pulled, preventing accidental activation. Additionally, "lock-on" features allow the user to maintain a closed circuit without continuous finger pressure, which is beneficial for long-duration tasks like sanding or mixing, though these are often omitted in handheld cutting tools for safety reasons.

Technical Specifications and Selection Criteria

When selecting or replacing a trigger switch, it is vital to match the component to the electrical load and environmental conditions of the application. Failure to do so can lead to contact welding or catastrophic switch failure. Use the following table to identify key parameters for trigger switch evaluation:

| Parameter | Description |

| Amperage Rating | The maximum current the switch can handle without overheating. |

| Voltage Range | Compatibility with AC or DC power sources (e.g., 120V AC or 18V DC). |

| Ingress Protection (IP) | The level of sealing against dust and moisture, crucial for outdoor tools. |

| Cycle Life | The estimated number of actuations before mechanical or electrical failure. |

Maintenance and Troubleshooting Common Failures

Trigger switches are often the first point of failure in heavy-duty equipment due to their mechanical nature and exposure to debris. Proper maintenance can significantly extend their operational life. If a switch becomes "mushy" or fails to engage, it is often due to internal contamination or carbon buildup on the contact points.

- Clean the housing regularly using compressed air to remove conductive dust.

- Inspect for "pitting" on the contacts, which indicates excessive arcing.

- Check the return spring tension to ensure the switch snaps back to the "off" position immediately.

- Test continuity using a multimeter to verify if the electrical path is truly broken when the trigger is released.

The Future of Trigger Switch Design

The industry is currently shifting away from traditional carbon-brush based rheostats toward brushless motor controllers and digital triggers. Modern trigger switches are increasingly becoming "smart" interfaces that communicate with microprocessors via pulse-width modulation (PWM). This allows for features like "soft start," where the motor gradually ramps up speed regardless of how quickly the trigger is pulled, and electronic braking, which stops the tool instantly upon release. These advancements not only improve the user experience but also enhance the overall safety and longevity of the device.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى