-

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

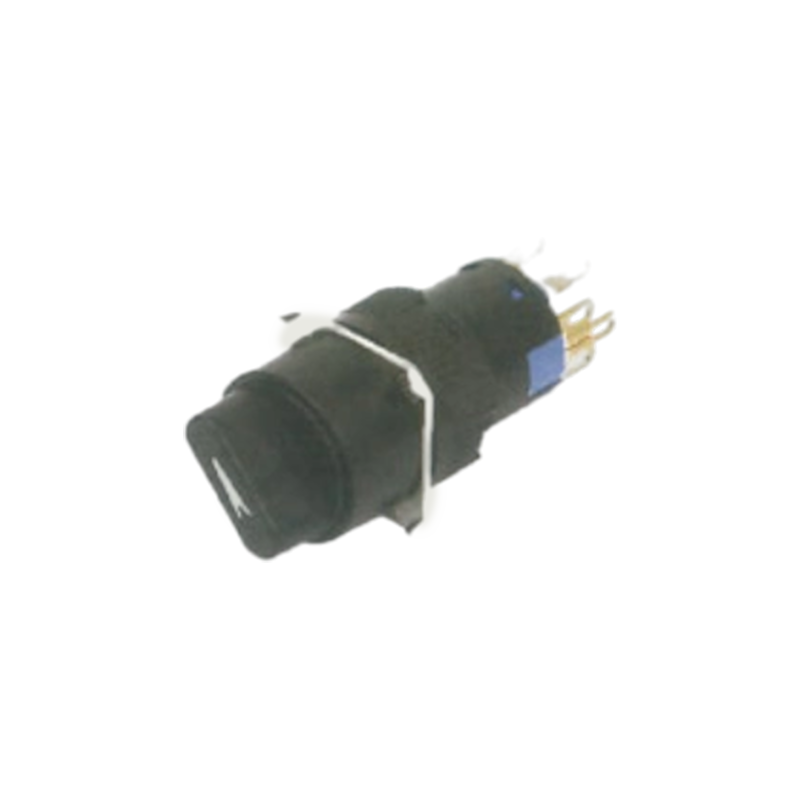

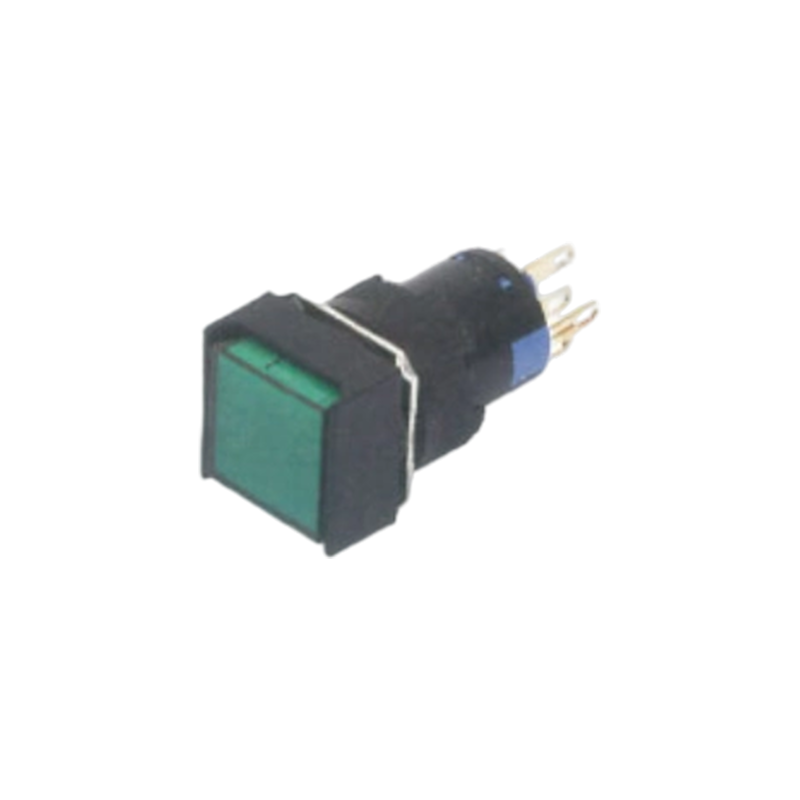

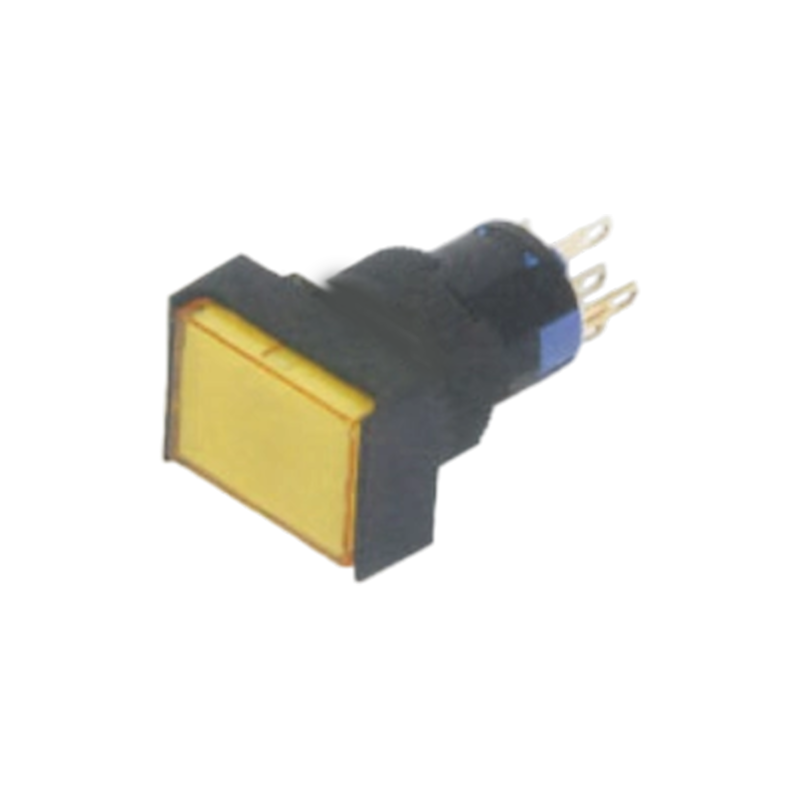

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

A Deep Dive into High-Precision Micro Switch Engineering and Applications

2025.12.24

2025.12.24

Industry News

Industry News

Understanding the Mechanics of Micro Switch Actuation

A micro switch, technically known as a miniature snap-action switch, operates on a unique "over-center" mechanism. This design allows a very small physical force applied to an actuator to result in a rapid movement of the electrical contacts. The speed at which the contacts transition is independent of the speed at which the actuator is moved, ensuring a crisp, repeatable response. This high-speed transition minimizes arcing and mechanical wear, which is why these components are preferred in high-precision environments where reliability is non-negotiable.

The internal structure typically consists of a spring-loaded lever that flips the contact position once a specific "trip point" is reached. When the pressure is released, the spring tension pulls the lever back to its original state at a designated "reset point." This physical hysteresis—the distance between the operating and releasing points—is a critical specification for engineers when designing sensitive control systems.

Key Technical Specifications for Selection

When integrating a micro switch into a circuit, several parameters must be evaluated to ensure longevity and safety. Choosing a switch based solely on size often leads to premature failure if the electrical load or environmental conditions are not properly matched to the component's capabilities.

Electrical and Mechanical Factors

- Operating Force (OF): The amount of force required to move the actuator from the free position to the operating position.

- Contact Configuration: Most micro switches utilize a SPDT (Single Pole Double Throw) setup, offering both Normally Open (NO) and Normally Closed (NC) options.

- Ingress Protection (IP Rating): For industrial or outdoor use, switches with IP67 ratings are essential to prevent dust and moisture from interfering with the internal spring mechanism.

- Mechanical Life: High-quality micro switches are often rated for 1 million to 10 million cycles, depending on the spring material and housing durability.

Comparison of Common Micro Switch Actuator Types

The method of physical interface—the actuator—determines how the switch interacts with the rest of the machinery. The following table highlights the most common types used in modern manufacturing.

| Actuator Type | Best Use Case | Primary Advantage |

| Pin Plunger | Short, direct linear strokes | Highest precision and repeatability |

| Hinge Lever | Low-force applications | Mechanical advantage for light touch |

| Roller Lever | Cam or slide operation | Reduces friction and side-loading wear |

| Simulated Roller | Economic cam tracking | Good for basic curved path detection |

Industrial and Consumer Applications

Micro switches are the unsung heroes of modern automation. In the automotive sector, they are used to detect whether a door is latched or if a seatbelt is buckled. In household appliances, they act as safety interlocks; for instance, a microwave oven will not operate unless the micro switch confirms the door is fully closed. Their ability to handle high cycles makes them ideal for these frequent-use scenarios.

In industrial environments, these switches serve as limit switches on CNC machines and 3D printers, defining the boundaries of movement for the tool head. By providing a physical "hard stop" signal to the controller, they prevent mechanical crashes and ensure the equipment remains calibrated during complex operations.

Installation Best Practices for Longevity

To maximize the lifespan of a micro switch, proper installation is paramount. Over-tightening mounting screws can warp the plastic housing, leading to internal misalignment and inconsistent switching points. Furthermore, ensuring that the actuator is not pushed beyond its "total travel" limit prevents the internal spring from being over-stressed, which is the leading cause of mechanical fatigue.

Soldering and Wiring Precautions

- Apply heat for the shortest duration possible when soldering to prevent the internal terminals from shifting in the plastic base.

- Use appropriate wire gauges that match the current rating of the switch to avoid overheating at the connection points.

- Implement arc suppression circuits (such as RC snubbers) when switching inductive loads like motors or solenoids to protect the contacts from pitting.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى