-

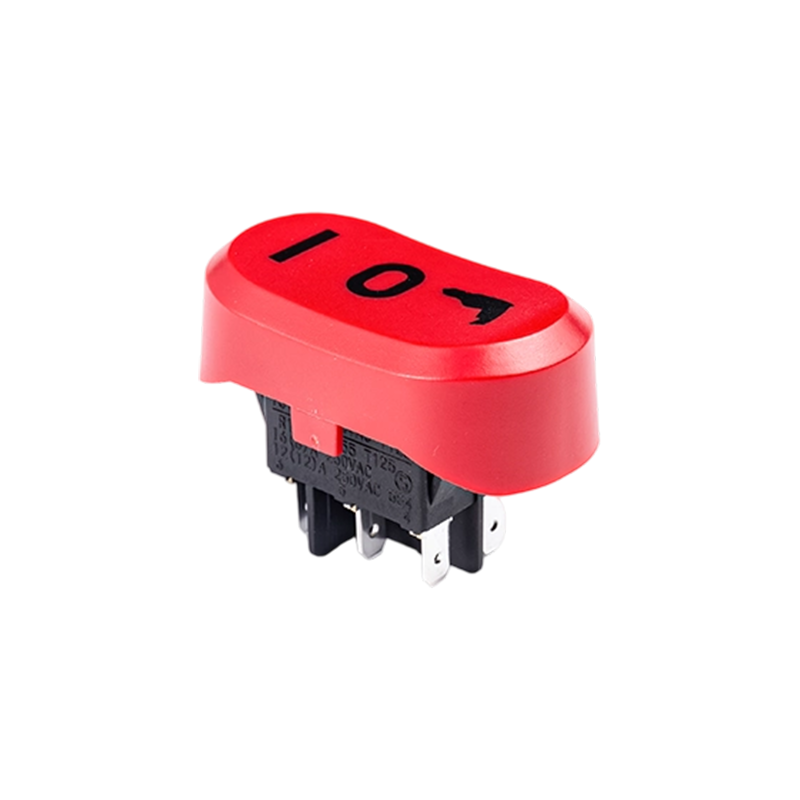

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

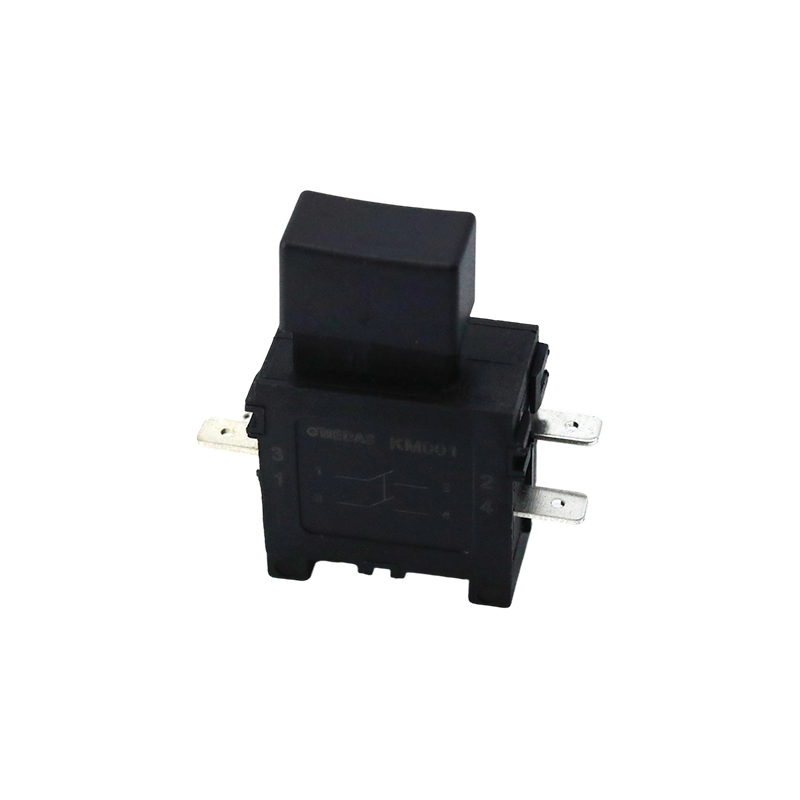

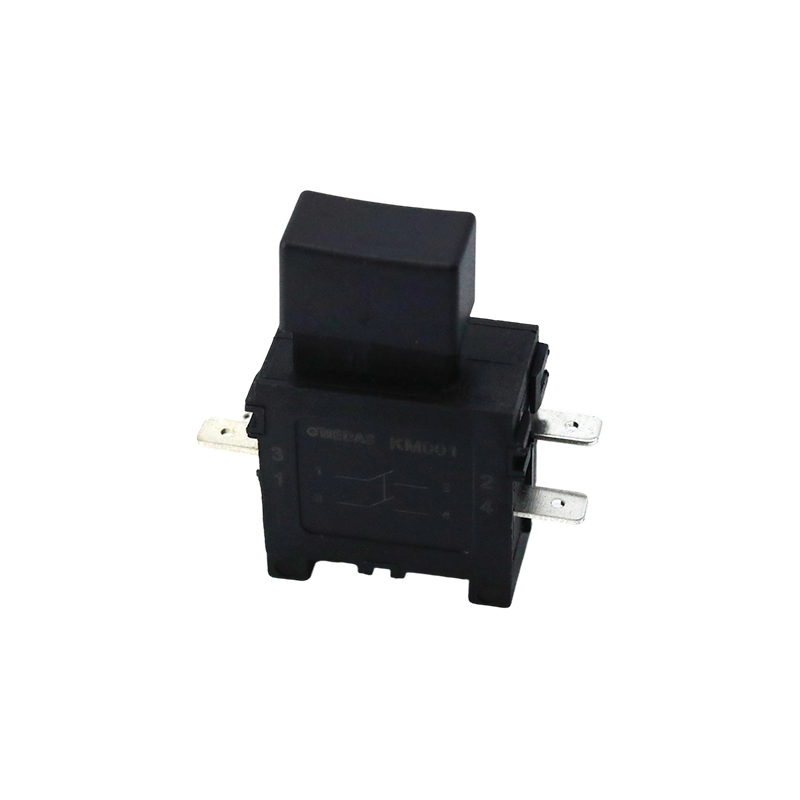

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

How Can High-Performance Trigger Switches Improve Power Tool Safety and Precision?

2026.02.04

2026.02.04

Industry News

Industry News

Understanding the Mechanics of Modern Trigger Switches

Trigger switches serve as the primary interface between a user and a power tool, acting as the gateway for electrical current to reach the motor. Unlike simple on-off buttons, high-quality trigger mechanisms are engineered to handle significant electrical loads while providing tactile feedback. They often incorporate internal springs that ensure the switch returns to the "off" position immediately upon release, a critical safety feature known as a dead-man's switch. This prevents tools from running unattended if dropped or misplaced during operation.

Beyond basic connectivity, advanced trigger designs utilize variable speed control. This is achieved through a built-in potentiometer or an electronic module that senses the depth of the trigger pull. As the user pulls the trigger further, the resistance changes, allowing the tool to increase its RPM or torque. This precision is essential for tasks like driving delicate screws or starting a drill bit without slipping on a hard surface.

Common Variations and Types of Power Tool Triggers

Depending on the specific application, manufacturers employ different variations of trigger switches to optimize performance and ergonomics. Choosing the right type depends on whether the tool requires constant activation, high-current handling, or intricate speed modulation. Below are the most common types found in professional-grade equipment:

- Single-Pole Single-Throw (SPST): The simplest form, used for basic on/off functions in stationary or high-power tools.

- Variable Speed Triggers: Integrated with electronic speed controllers (ESC) to provide a range of power outputs based on finger pressure.

- Lock-On Triggers: Feature a side button that holds the trigger in the "on" position, reducing hand fatigue during long-duration tasks like sanding or grinding.

- Reversing Trigger Assemblies: Common in drills, these include a secondary lever near the main trigger to flip the polarity of the motor.

Comparing Trigger Switch Specifications for Heavy-Duty Use

When selecting or replacing a trigger assembly, it is vital to match the electrical ratings to the tool's motor requirements. Using an under-rated switch can lead to contact arcing, overheating, and eventual melting of the switch housing. The following table highlights key specifications to consider for heavy-duty trigger switches:

| Feature | Description | Importance |

| Amperage Rating | Typically 5A to 20A | Prevents internal burnout |

| Dust Protection | IP54 or Sealed Housing | Increases lifespan in woodshops |

| Cycle Life | 50,000+ Activations | Ensures long-term reliability |

Safety Features and Maintenance of Control Switches

Electronic Braking and Soft Start

Modern trigger switches are often paired with "soft start" technology, which gradually ramps up the voltage to the motor. This prevents the tool from "jerking" in the user's hand upon activation, which is particularly important for high-torque circular saws or routers. Additionally, some triggers include electronic braking that stops the blade or bit within seconds of releasing the trigger, significantly reducing the risk of accidental injury.

Preventative Maintenance for Longevity

Because power tools often operate in dusty environments, the internal contacts of trigger switches can become fouled with debris. This leads to "intermittent" operation where the tool may stutter or fail to start. Periodically using compressed air to blow out the area around the trigger can prevent buildup. If a switch feels "crunchy" or fails to spring back, it should be replaced immediately to ensure the safety of the operator.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى