-

A Rocker Switch is a compact and easy-to-operate manual control component. Its unique rocker-style actuation, combined with a toggle or momentary reset function, allows users to quickly switch circuit...View More >>

-

A micro switch is a small mechanical switch with a fast action mechanism, which is widely used in household appliances, industrial automation, automotive electronics, medical equipment, and other fiel...View More >>

-

Push button switches are widely used in various control systems with their diverse structural designs, high-strength material selection, and excellent performance. The products are available in a vari...View More >>

-

The internal structure of the piano key switch mostly adopts a mechanical or light-touch design. Some high-end models use capacitive sensing technology to achieve contactless operation, thereby improv...View More >>

-

The baby stroller gear switch is an innovative product independently developed by our company. We have applied for invention patents both domestically and internationally, which fully demonstrates the...View More >>

-

The knob switch adopts a high-sensitivity rotary contact structure, which has smooth operation and clear positioning, ensuring that every adjustment is accurate. The product has excellent durability a...View More >>

-

The KM trigger switch is a universal high-current switch designed for high-power power tools, with excellent current carrying capacity and stable performance. The internal fast-action structure ensure...View More >>

-

A door control switch, also known as a door magnetic switch or door status sensor, is a key electrical component widely used in industrial control, security systems, intelligent building automation, a...View More >>

-

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is ...View More >>

-

PCB control board is one of the indispensable core components in modern electronic devices. As the brain of the control system, it is widely used in many fields such as industrial automation, consumer...View More >>

Wiring Harness Manufacturers

The wiring harness is an overall wiring assembly that integrates multiple wires, cables, terminals, and connectors according to specific electrical design and mechanical structure requirements. It is widely used in many fields such as industrial automation, automotive electronics, communication equipment, new energy, medical instruments, and household appliances. This series of products uses high-quality copper core conductors and environmentally friendly insulation materials, has excellent conductivity and environmental resistance, and supports multiple characteristics such as anti-interference, high-temperature resistance, oil resistance, wear resistance, flame retardancy, etc., to ensure stable operation under complex working conditions. The product has a compact structure and a reasonable layout, which effectively improves assembly efficiency and the stability of the whole system. This series of products has passed many authoritative certifications such as UL (USA), TUV (Germany), KC (South Korea), CQC (China), etc., and complies with industry standards such as IEC 62255, ISO 6722, GB/T 18164, and meets environmental regulations such as RoHS and REACH. It is suitable for global markets such as North America, Europe, and Asia.

About SHQIJIA

Shanghai Qijia Electronics Co., Ltd. was founded in 2004. After more than two decades of development and accumulation, it has grown into a high-tech enterprise integrating the design, R&D, manufacturing, sales, and service of high-quality appliance switches, as Wiring Harness Manufacturers and Wiring Harness Manufacturers in China, we establish a professional and reliable brand image in the industry.

The company's core product line, "shqijia," covers a wide range of AC and DC appliance switches, including micro switches, rocker switches, pushbutton switches, trigger switches, and rotary switches, as well as AC and DC circuit board modules and controllers. These products are widely used in AC and DC power tools, electric garden tools, cleaning equipment, household appliances, medical equipment (oxygen concentrators), generators, electric strollers, water pumps, and other electronic and mechanical fields, providing customers in various industries with highly adaptable core component solutions.

In 2025, the company opened a new factory Withover 20 assembly lines, more than 20 injection molding machines, and over 40 automated equipment, the company boasts an annual production capacity exceeding 80 million units, providing stable and efficient product supply support to customers worldwide. In addition, we support Factory Direct Oil-Resistant Wear-Resistant Flame-Retardant Wiring Harness, the company possesses professional independent product and mold design capabilities, providing customized development services based on individual customer needs and precisely matching diverse application scenarios.

With superior quality, advanced manufacturing processes, competitive pricing, and comprehensive after-sales service, Qijia has earned widespread recognition and trust from customers worldwide.

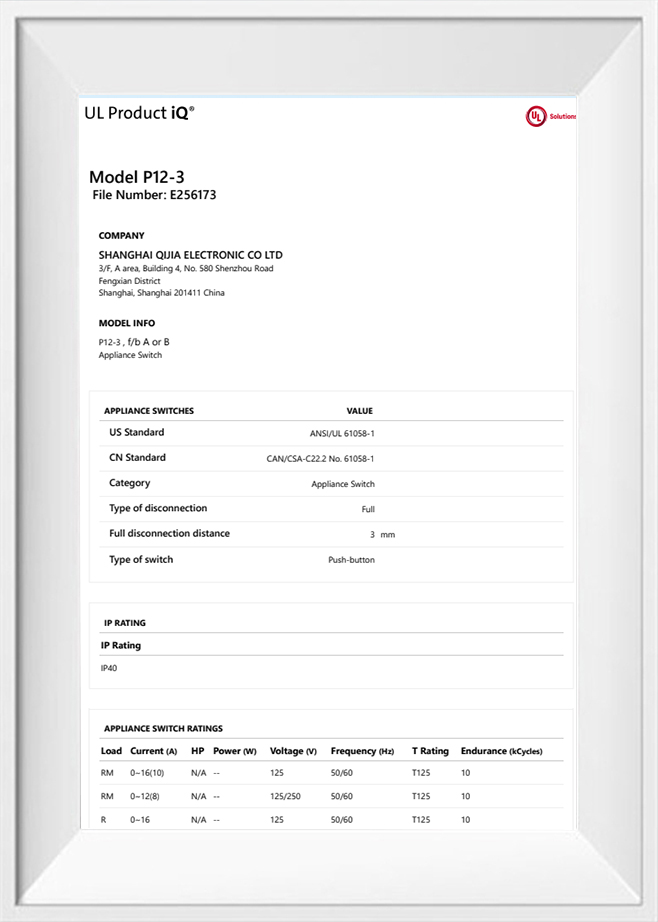

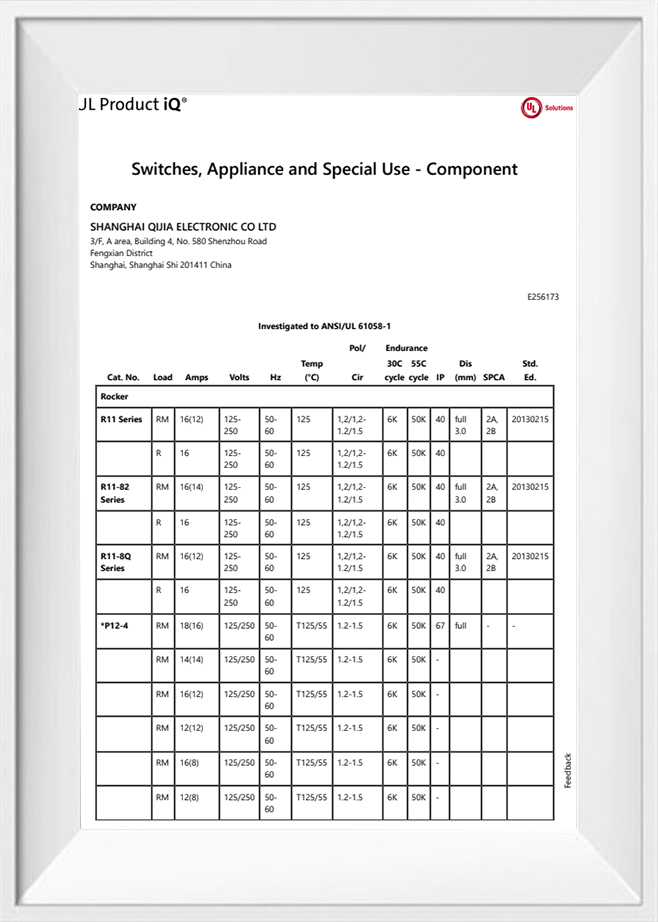

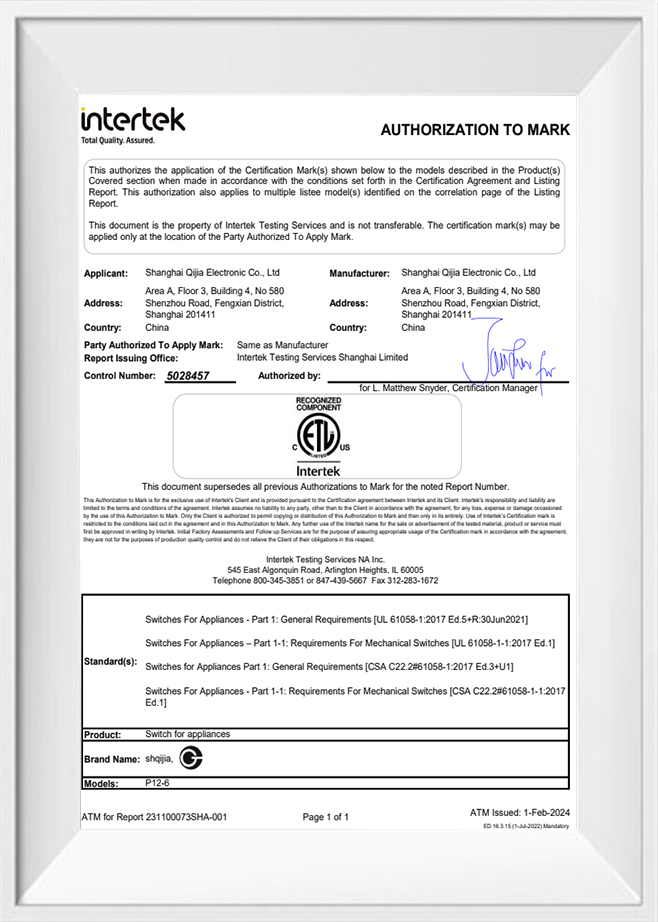

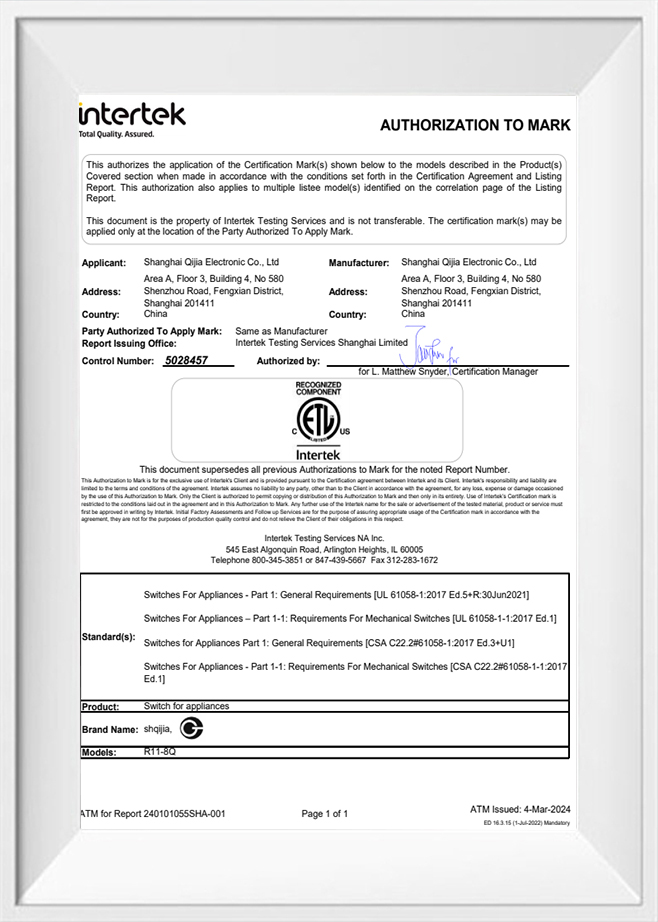

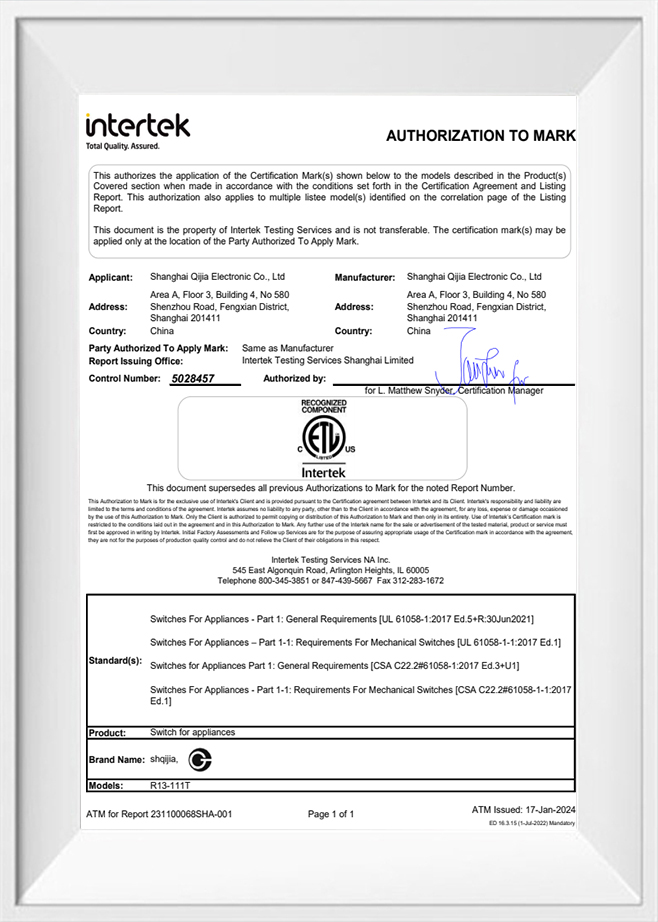

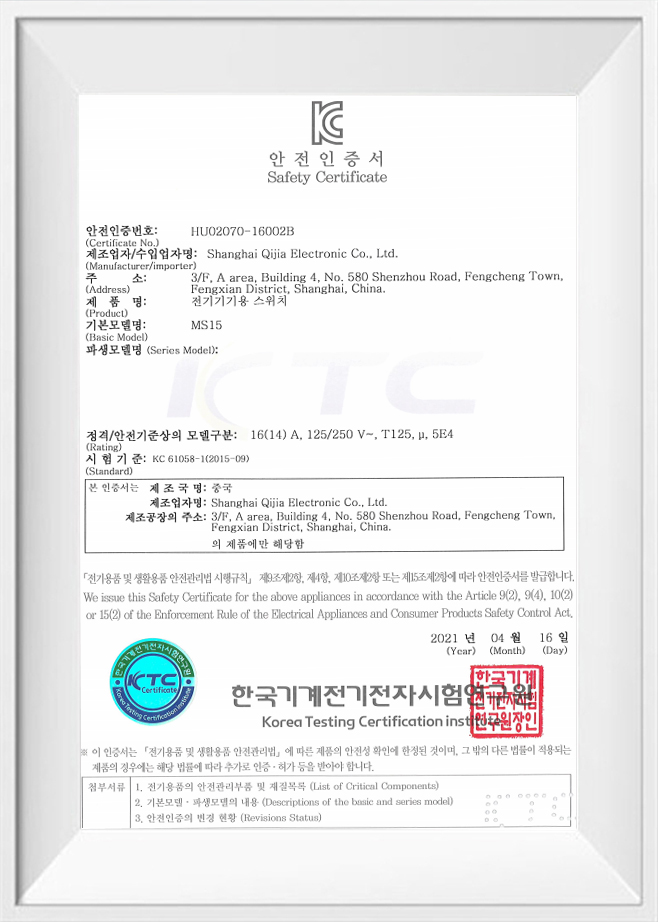

Certificate

Latest Updates

Industry knowledge

Key Advantages of High-Quality Copper Core Conductors in Wiring Harnesses

Wiring harnesses featuring high-quality copper core conductors are essential for ensuring superior electrical conductivity and performance. The use of copper, with its excellent electrical properties, minimizes energy loss and enhances system efficiency, particularly in high-demand applications such as automotive, industrial, and renewable energy sectors. With the added benefit of resistance to oxidation and corrosion, these copper core wiring harnesses guarantee long-lasting reliability in harsh environments.

Our wiring harnesses with copper conductors ensure maximum electrical efficiency, while providing a robust solution for your most critical electrical connections. The exceptional conductivity helps reduce heat generation, which is vital in preventing overheating issues that can affect the overall performance of electrical systems. Whether for automotive or industrial machinery, this feature is a key reason why our products are chosen by clients globally.

Why Insulation Materials Matter

The insulation materials used in wiring harnesses are just as important as the conductors themselves. We use environmentally friendly insulation materials that meet strict safety standards, such as RoHS and REACH, to ensure that our wiring harnesses are safe for both the environment and the user. These materials not only provide superior electrical insulation but also offer impressive resistance to various external factors like high temperatures, oils, and wear and tear.

Our customers trust us because we go the extra mile in choosing materials that enhance performance, safety, and sustainability. The insulation materials used in our wiring harnesses support flame retardancy, wear resistance, and high-temperature resistance—key attributes needed for ensuring the long-term integrity of electrical systems, even under the harshest working conditions.

Certification and Compliance: Meeting Global Standards

One of the critical aspects of our wiring harnesses is their adherence to international standards and certifications. Our products have earned certifications from leading global organizations, including UL (USA), TUV (Germany), KC (South Korea), and CQC (China). These certifications provide assurance of our products' safety, performance, and environmental responsibility.

With compliance to industry standards like IEC 62255, ISO 6722, and GB/T 18164, our wiring harnesses are built to meet the rigorous demands of various industries. These certifications are proof of our commitment to quality and safety, ensuring that our products can be relied upon in markets across North America, Europe, and Asia.

Environmental Compliance

We also prioritize environmental sustainability by adhering to regulations like RoHS and REACH. These regulations ensure that our wiring harnesses do not contain hazardous materials, which makes them safe for both users and the environment. With global environmental concerns rising, it’s crucial that we play our part in reducing the ecological impact of electrical components, and this is a promise we deliver on every day.

Optimizing Wiring Harness Performance in Complex Systems

The structure and layout of a wiring harness play a significant role in system efficiency and stability. We focus on creating compact, well-organized wiring harnesses that simplify assembly and improve the overall performance of your systems. A carefully designed wiring harness minimizes the risk of electrical shorts, tangling, or interference, which can be particularly problematic in high-speed or high-voltage environments.

Our products are engineered with efficiency in mind, allowing for faster assembly and reduced production downtime. The streamlined design also enhances the stability of the entire system by ensuring that the electrical components are properly arranged and insulated from external factors that could interfere with performance. This is why our clients, from automotive to renewable energy sectors, trust us with their most critical wiring needs.

Customized Solutions for Unique Needs

We understand that every project has its own set of requirements, which is why we offer customized wiring harness solutions. Whether you need a specific length, connector type, or insulation material, we can tailor our products to meet your exact specifications. Our flexible production capabilities ensure that we can handle both large-scale manufacturing runs and smaller, specialized orders with ease.

Advanced Manufacturing for High-Volume Production

With over 150 employees and state-of-the-art automated equipment, we can achieve an annual production capacity of over 80 million units. Our advanced manufacturing processes—featuring over 20 assembly lines and 40 automated machines—ensure that we can meet high-volume demands while maintaining the highest levels of quality control. This allows us to deliver consistent, reliable products to our customers worldwide.

Our manufacturing excellence is paired with robust supply chain management to ensure timely delivery, even for complex and large-scale orders. No matter how demanding your project, we can provide the wiring harnesses you need, on time and to the highest standards.

English

English  русский

русский  Español

Español  Deutsch

Deutsch  عربى

عربى